PRODUCTS

New Challenge Technology

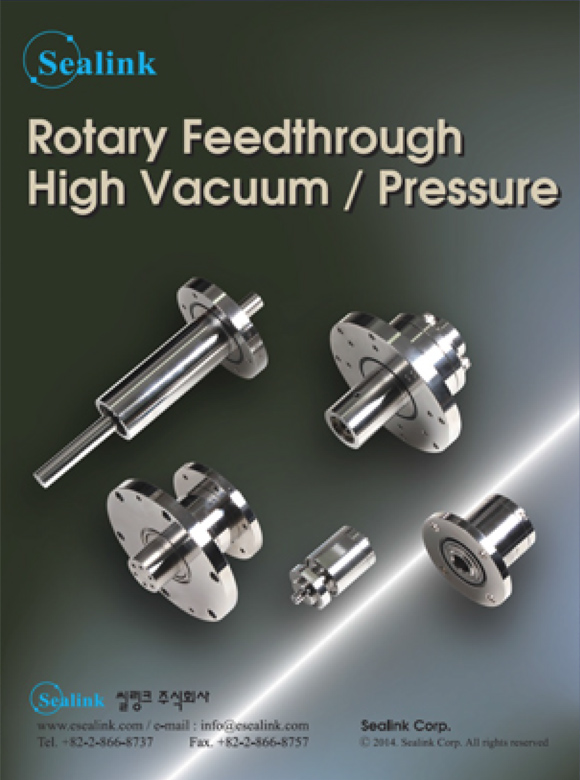

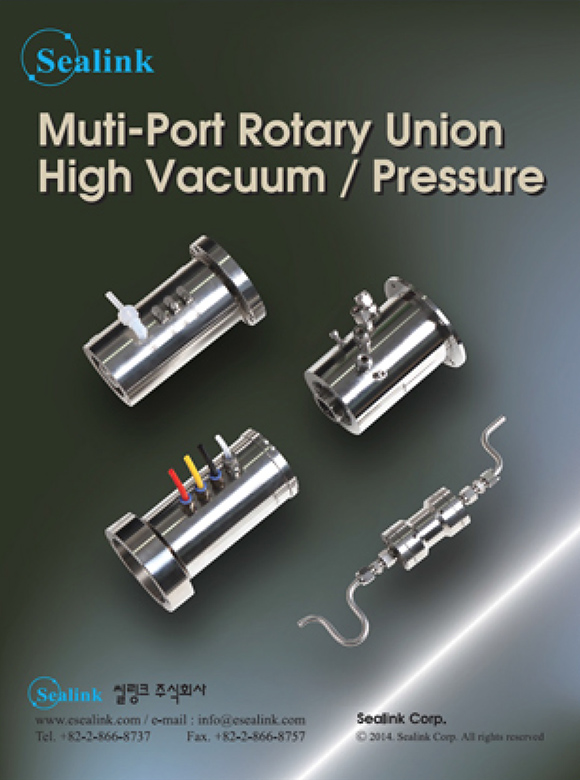

PARTS

Seal link

High temperature, high vacuum rotation/linear S-Seal unit for semiconductor equipment

-

-

Problem solving : no lubrication method > Deposition equipment, CMP

- No lubricant, No risk of explosion

- No lubricant, No product contamination

- No lubricant supply, No rick of explotion

-

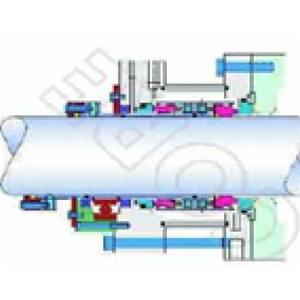

What is sealing device?

Device to prevent fluid from leaking into the gap between the rotating shaft and the housing crack in the chemical reactor

-

Problem solving : no lubrication method > Deposition equipment, CMP

Semiconductor: Intel(US)

Petrochemical : HYOSUNG, LG Chem

| Condition | Mechanical Seal | S-Seal(Seal Link) | Advantages |

|---|---|---|---|

| Driving method | Use of lubricant | No lubrication method | Product innovation |

| Lubricant supply device | Necessary | Unnecessary | Economics |

| loT technology | None | Real-time leak detection system | ICT convergence |

-

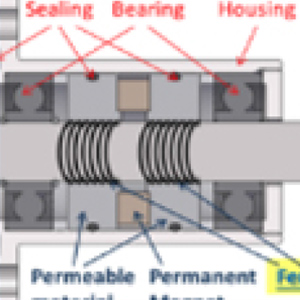

Existing competitive products : Research on surface contact field

- Seal link : Research on line contact field

| Condition | Mechanical Seal | S-Seal(Seal Link) | Advantages |

|---|---|---|---|

| Driving method | Use of Ferrofluid | Non-lubricating method | Product innovation |

| Cooling system(100℃) | Necessary | Unnecessary | Economics |

| loT technology | None | Real-time leak detection system | ICT convergence |

-

Existing competitive products : Research on magnetic fluid field

-

Seal link : Research on line contact field

| product Specification | Mechanical seal | Magnetic fluid seal | S-Seal |

|---|---|---|---|

| structure |  |

|

|

| Driving method | lubricant | Magnetic fluid | None-lubricant |

| Industrial field | Petrochemical | Semiconductor | Petrochemical+ Semiconductor |

| Conditions of use | pressure | vacuum | Pressure + vacuum |

| Price competition | High cost | High cost | 13% ↓ |

Price competitiveness 13%: Lubricant supply device 10% + Modularizatuib structure 3%

PV

- The first GFCs that were introduced were the GFC200, with a range of accuracy from 1 to 200 sccm, and the GFC2000 with range of accuracy from 10 to 2000 sccm.

- Samsung requested a lower flow GFC that would have a range of accuracy that extended to 0.1 sccm. The GFC20 was introduced to meet this need. Only the internal volume and the diameter of the valves were changed.

- Samsung then requested a GFC with a range of accuracy that extends to 0.025 sccm. We have introduced the GFC5, and once again, only the internal volume and the valve diameter needed to change.

MI

-

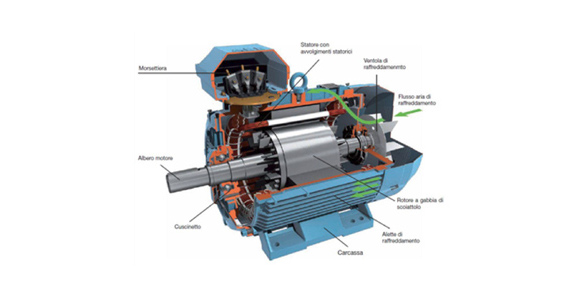

Vibrationseverity

-

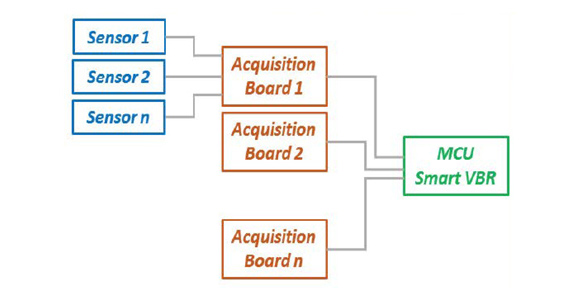

SystemArchitecture

VibrationSensor

AcquisitionBoard

MCU Smart VBR

| Transducer Technical Features | ||

|---|---|---|

| He(5N) | 50BT/M | 47L Mn-Steel, JISS 22R |

| L-N2, N2(5N) | 3,000BT/M | 47L Mn-Steel, JISS 22R |

| L-Ar, Ar(5N) | 7,000BT/M | 47L Mn-Steel, JISS 22R |

| CO2 (5N) | 1,200BT/M | 47L Mn-Steel, JISS 22R |

| H2 (5N) | 3,600BT/M | 47L Mn-Steel, JISS 22R |

| O2 (5N) | 1,800BT/M | 47L Mn-Steel, JISS 22R |

-

Functionalities

- Vibration Sensors sampling and acquisition;

- Signal elaboration and vibration severitiy computation;

- Datat ransmission and local representation of results throught multicolor LEDs.

| Acquisition Board technical features | |

|---|---|

| Supply voltage | 24V dc |

| Microcontroller | STM32F103ZET6 |

| Communication Port/Protocol | RS485/Modbus-RTU |

| Analog input(max) | 10 |

| Analog input sampling | 20kHz 24/16bit(ADC ext/u C |

| Power consumption(considcing 10inputs) | ≒1W |

| Storage temperature | -40°C - +85°C |

| Operating temperature | -40°C - +85°C |

| Climatic conditions | Indoor |

| Box materal | polymer |

| Box external size | 108 X 42 X 150 mm |

-

Functionalities

- Data acquisition form n Acquisition Bords through MODBUS RTU on RS-485 port;

- Parameters setting (10816-3 severity threshold) on Acquisition Boards;

- Visualization on integrated WEB server interface;

- Very user friendly graphica linterface;

- Instantaneus data reading through web browser or additional TCP client for medium/long term monitoring, trend analysis, statistics, preventive and predictive maintenance, report, SCADA, etc...

| MCU Smart VBR technical features | |

|---|---|

| Supply voltage | 15-24V dc |

| Microcontroller | PIC18F97J60 |

| Communication Port/Protocol | Ethernet IEEE 802.3 10Base T RJ-45/Modbus-PTU |

| LCD Display | Optional |

| WEB Server | Integrated |

| Size | 2DIN modules |